Manufacture

How do we make our boats?

Manufacture

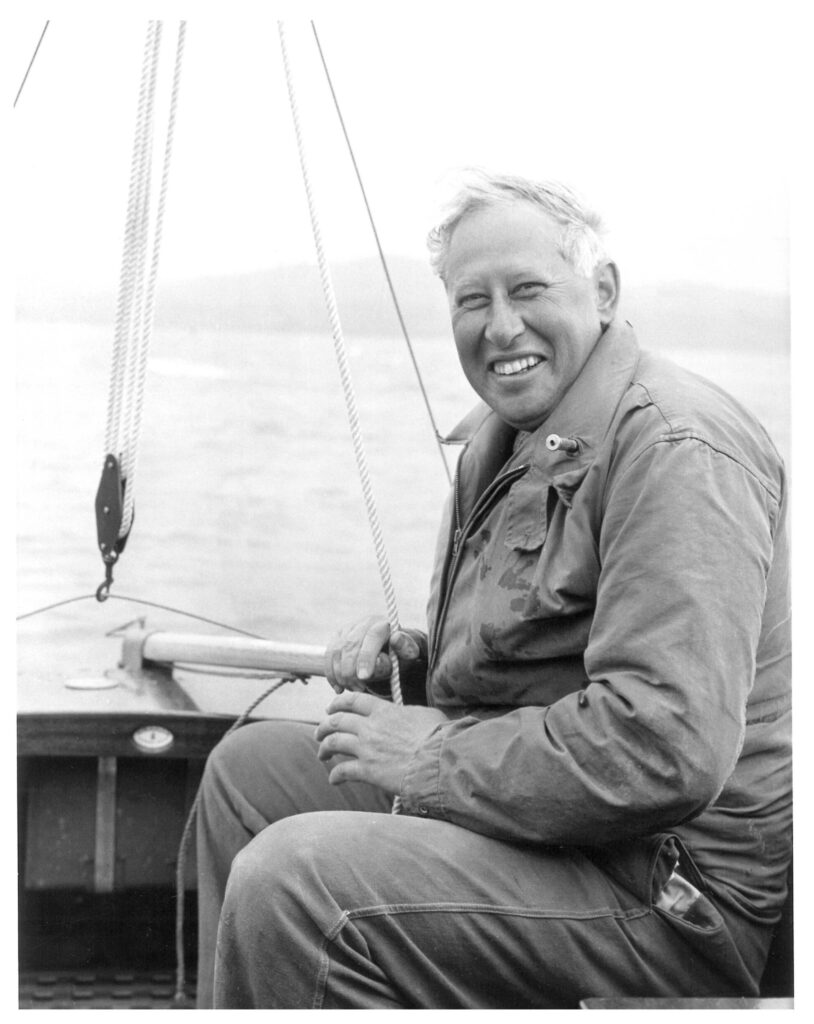

The History of Topper

A true pioneering British Design, the Topper was originally conceived by Ian Proctor, Royal Designer for Industry, and has been in production since the early 1970s.

Instantly recognisable, Topper is well renowned among sailors after over 40 years of continuous production. Receiving numerous international design awards, it has remained virtually unchanged in its form, being a real testament to its ground breaking design and innovative engineering.

The outstanding build quality and unique features keep Topper one of the most popular boats in the world, and will continue to do so for years to come.

Changing from polypropylene to polyethylene.

In 2023, our original production method of injection moulding was updated to our signature rota-moulding technique used on Topper International’s Topaz range. At the same time we took the chance to make a few improvements to the sailing experience too. This manufacturing change has safeguarded the future of this iconic design, bringing it bang up to date.

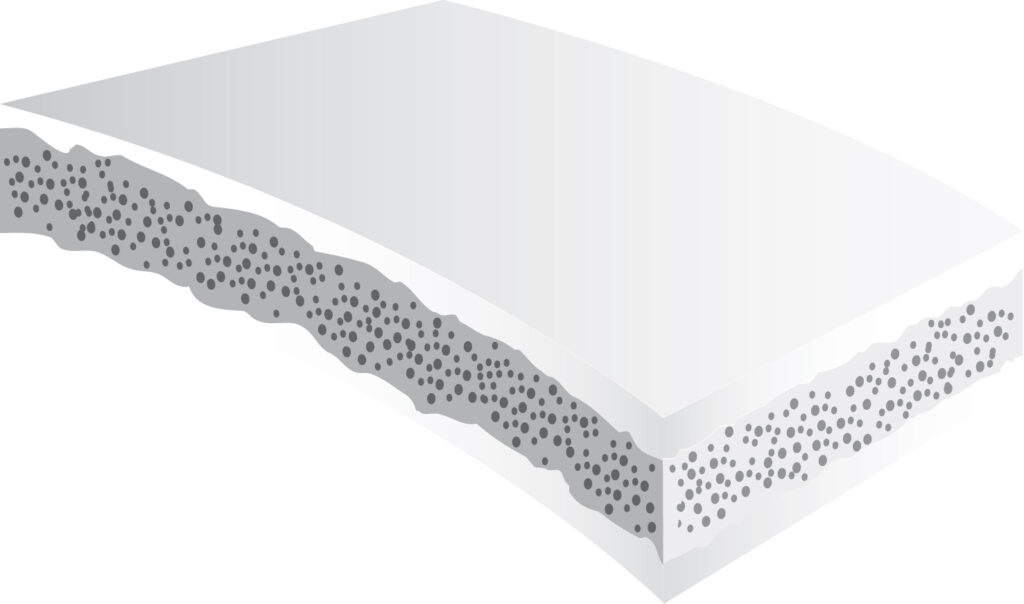

Our Process

The three layer TRILAM sandwich guarantees that no other rota-moulded sailboat can compare in terms of strength, rigidity and durability. With a lightweight, extra-strength honeycomb core and exceptional Metalicence outer and inner skin, it ensures toughness without increasing hull weight.

Hardwearing

Our manufacturing technique is proven to be 41% stiffer and 25% tougher than standard polyethylene construction. Making our boats far stronger than the competition!

Quality Assured

With build quality second to none, all our boats come with a 3 year guarantee as standard. Should anything go wrong you can rest assured you’ll receive outstanding aftercare.

UV Stabilised

Fading, cracking, or compromised quality? Not on our watch! All of our boats are fully UV stabilised to protect your investment against the elements both sea and sky!